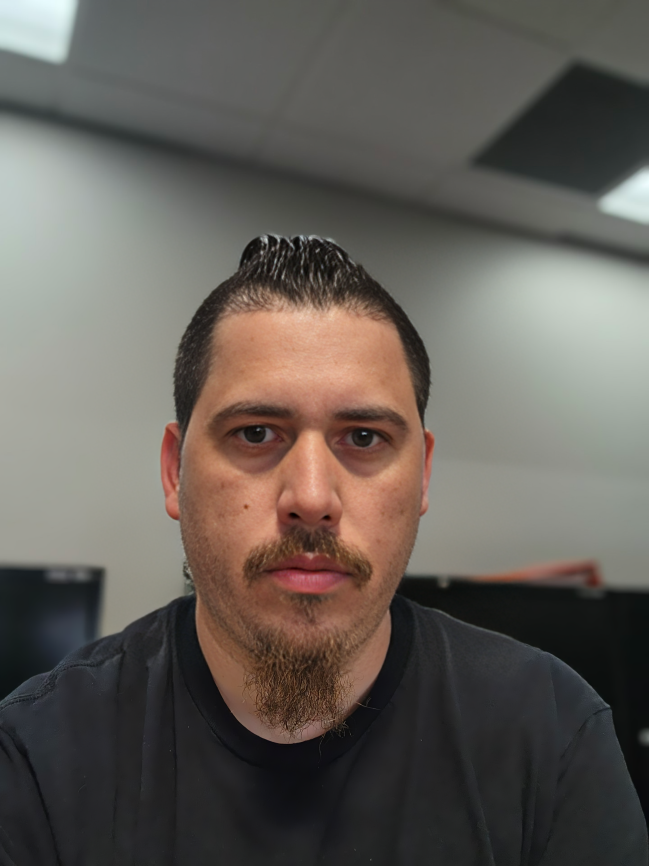

Danon Neves has played a pivotal role for the past five years at Konnected Technology. His journey at the company has seen him take on various roles, from being the main point of contact to leading tech support and ultimately becoming a project manager for their critical IS projects, serving one of Konnected’s major clients in the United States. Read more to learn more about Danon Neves journey as an engineer.

1. Can you tell us a bit about your background?

I actually started out as an electrician at 19 and did that for about 6 years. After that I did a little bit of low voltage fire alarm installation. After a couple years of that I got into the tech side of things working for a wireless communication company. WIth that company I did a little bit of work on the WISP (Wireless Internet Service Provider) side of things but my main focus was being their lead tower technician. I was the lead installer for all of their wireless tower jobs that were in-house for the WISP side of the business or that were contract jobs for companies that did not have their own tower climbers. With them I would also run the jobs installing remote camera systems for companies and ranches that did not have a conventional way to get them installed. These were usually run off of solar systems in very remote locations. As well as that we would install WiFi systems for companies with remote locations for their employees. From there I went into tech support at a hospital in Montana. I started out as a telecommunication tech then pretty quickly moved up to being one of the lead Desktop Support Analysts. Once they opened a 2nd emergency access hospital I was the lead support onsite there and back at the main hospital till I came back home to Texas. Once I was back in Texas for about 6 months is when I came on with Konnected Technology and have been with them for about 5 years now. Since being here I have been the main point of contact, tech support lead, and now project manager on all of their IS projects for one of Konnected’s largest customers in the US.

2. What do you find most exciting or fulfilling about your role and the work you do at Konnected?

One of the things I like most about the work I do is being able to take a customer’s needs and being able to help them turn it into a usable system to meet their needs. After getting with a customer, determining their needs, and then being able to work with our team at Konnected it is great to see when the customer is happy with the end product that we deliver.

3. Could you share a notable project or accomplishment that you’ve been involved in?

One of the bigger projects that I have been a part of is the Sequencing system that was developed for a manufacturing company we are involved with. This system is a custom system that was put in to replace an existing system they were very unhappy with. Once we put our system in place not only were they extremely happy with the product. After that they invited the president of one of their biggest customers and I was called by our customer to let me know how happy and impressed everyone one was by the system we implemented. That was a very good call to receive.

4. In what ways do smart systems help mitigate the risks in manufacturing facilities?

They help to take the guesswork away from the human side of the work. Once implemented properly a smart system does most if not all of the complicated decision making. With this not only does it mitigate the risks but speeds up manufacturing and increases quality of the product.

5. What advice would you give to aspiring engineers who are interested in pursuing a similar career path?

Keep doing what interests you. The more you are interested in what you are actually doing the better the results will be and the more you will learn for anything you need in the future.